| Station speed | 1800PCS/H |

| Applicable lamp cap model | E26 E27 |

| Applicable bulb diameter | 0.6MPa≤P≤1MPa |

| Working pressure | 220V 50Hz |

| Power supply | 15KW |

| Equipment Weight | 1200kg |

| Machine diamension(LXWXH) | 1600mmx3000mmx1670mm |

Applications:

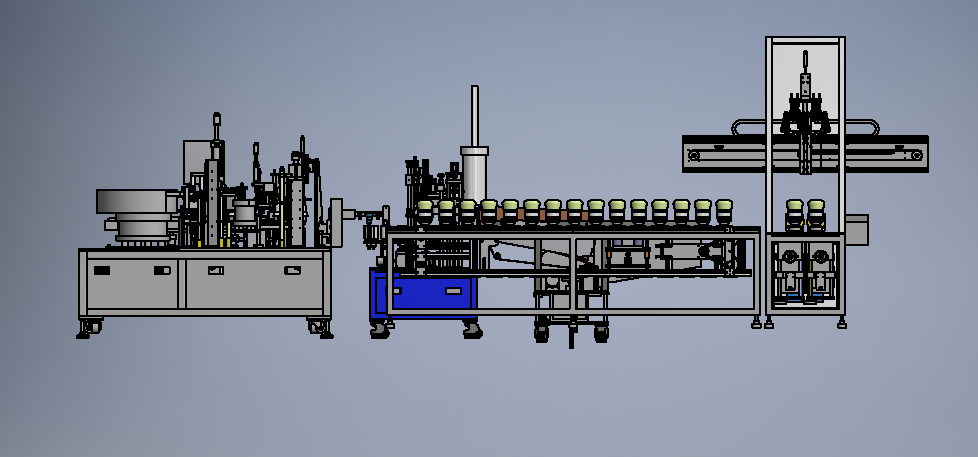

This product is a new model developed by our company for the standard specifications of bulb lamps at home and abroad. This is a fully automatic assembly line of led bulb lamp,only need 3 workers. The assembly production line includes automatic cover conveying machine, automatic light source plate(PCB board/led chip) pressing machine, automatic gluing machines, automatic cover assembly machine, automatic lamp head(E27 base) assembly,crimping and riveting machine, aging line,and automatic laser marking machine.The main procedures are PCB board(led chip) pressing,bulb housing gluing,bulb cover assembly,E27 base assembly,crimping and riveting,electricity measurement,aging test,logo print. Suitable for E26/E27 base bulb.

Features:

This machine uses a cam divider, which uses a combination of cams and cylinders to achieve the action process. Precise positioning and high product qualification rate.After professional design, the work station can realize a variety of products.There is stable performance and simple operation,it is easy to maintain.

The lamp head is tomatically loaded with a vibration plate.The lamp cup is automatically fed by a conveyor belt.The machine adopts a flipping mechanism for blanking,be used in conjunction with the bulb assembly machine,can also be used alone.

The production line uses a variety of equipment to run in series,suitable for mass production of single specification.Each section of equipment has an independent control system to avoid one link failure and increase production across the board. Each section of equipment is equipped with a Foma wheel to facilitate the free movement and handling of the equipment.